Laser cutting mailbox industry pain points breakthrough: Which deburring process has the highest cost performance?

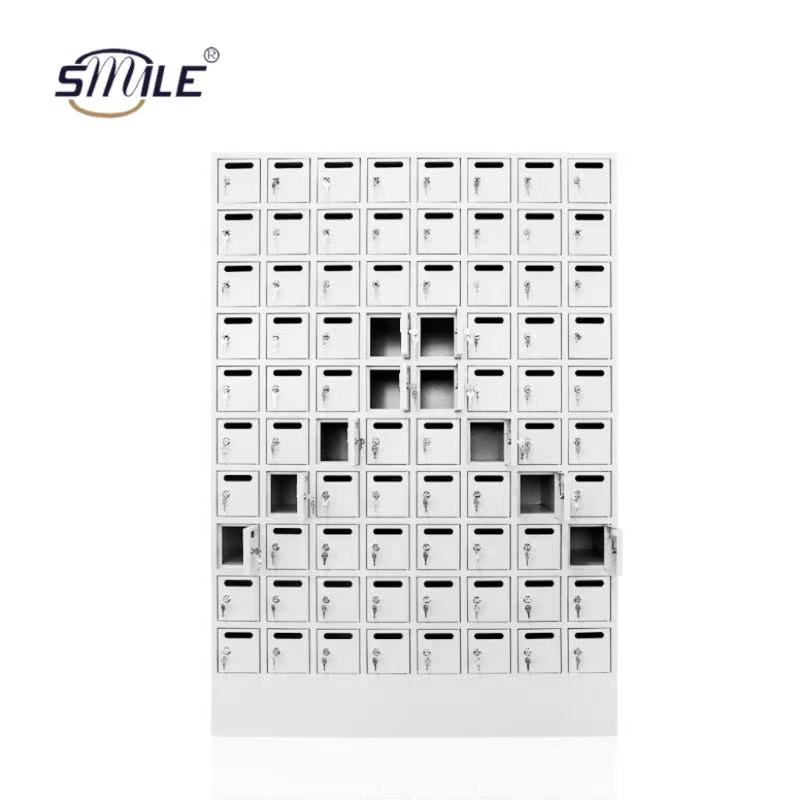

With the growth of demand smart mailboxes, community letterbox and express parcel boxes, the burr problem in sheet metal processing is increasingly highlighted. Our reporter found that the burrs on the laser-cut plates not only affect the appearance of the mailbox but also lead to frequent installation scratches. Which deburring process is most suitable for the mailbox manufacturing industry?1. Industry pain: Burrs become the "invisible killer" of mailbox manufacturingRecently, property complaints in many places have pointed out that newly installed metal letterbox have the phenomenon of edges hands. After testing, this is mainly due to the incomplete treatment of burrs on steel plates after laser cutting:

A certain brand of smart parcel box has a damaged sealing due to burrs, resulting in a 40% increase in leakage rate

Community centralized mailbox installation workers reflect that 3 out of every 10 need to be returned grinding

"The traditional manual grinding efficiency is too low," said the production director of a mailbox manufacturer, "We urgently need a high-cost-effective deburring solution"2. Industry upgrade: From mailbox to smart parcel box qualitative change Manufacturers who adopt new processes have already received returns:

After upgrading the production line, complaint rate of community mailbox has decreased by 67%A certain cross-border e-commerce parcel box adopts magnetic polishing, and the export order has increased by35%"This is not a simple technical choice," pointed out the secretary-general of the China Hardware Association, "It is related to the quality foundation of the mailbox industry from traditional letterboxes to smart parcel boxes."3. Future trend1. Composite process: Vibration grinding manual re-inspection becomes new standard for letterbox manufacturing

2. Material innovation: Pre-coated steel plates can reduce 60% of burr generation

3. Intelligent detection: AI vision are being piloted for finished mailbox inspection

Manufacturers who adopt new processes have already received returns:

After upgrading the production line, complaint rate of community mailbox has decreased by 67%A certain cross-border e-commerce parcel box adopts magnetic polishing, and the export order has increased by35%"This is not a simple technical choice," pointed out the secretary-general of the China Hardware Association, "It is related to the quality foundation of the mailbox industry from traditional letterboxes to smart parcel boxes."3. Future trend1. Composite process: Vibration grinding manual re-inspection becomes new standard for letterbox manufacturing

2. Material innovation: Pre-coated steel plates can reduce 60% of burr generation

3. Intelligent detection: AI vision are being piloted for finished mailbox inspection

From the letterbox at the front door to the parcel box of the express cabinet, the "small process" of deburring is driving the upgrade. Choosing the right process is not only responsible for the product quality but also a commitment to the safety of millions of users.