In today's precision manufacturing field, CNC is undoubtedly the mainstay, playing an irreplaceable role, with deep technical precipitation and rich practical experience, CHNSMILE has become a trusted partner of excellence in the industry, and won the high praise and wide recognition of many customers. CNC is the core technology in the field of precision manufacturing, in the scene of metal machining, parts customisation and so on. CNC is the core technology in the field of precision manufacturing, and it is the "precision tool" in metal machining, parts customisation and other scenarios!

But what exactly is CNC, and how does it work? Why has it gained popularity in so many industries? Next, we will dismantle these questions one by one, and at the same time introduce you to the characteristics and applications of several common metals, providing you with a full range of references for the selection and processing of materials for your projects.

Working Principle

The machining requirements are first translated into computer-recognisable code, specifying the machining path, speed and accuracy parameters.

After the code is entered into the CNC control system, the system parses the commands and drives the machine's motors, tools, and other components.

The machine tool accurately completes cutting, drilling, milling and other processing actions according to the preset programme, with full automation and minimal error.

CNC machining is widely used in many industries such as aerospace, automotive manufacturing, medical devices, electronic products, industrial robots, energy equipment and so on, by virtue of its advantages of high precision, strong stability and adaptability to the processing of complex parts. It can not only meet the processing needs of turbine blades, artificial joints and other high-precision complex parts, but also guarantee the quality and efficiency of products such as electrical shells and motor housings, and also extend the service life of the core components of energy equipment, which has become the key support for precision manufacturing in various industries.

Comparison of cnc machining process

1.CNC turning

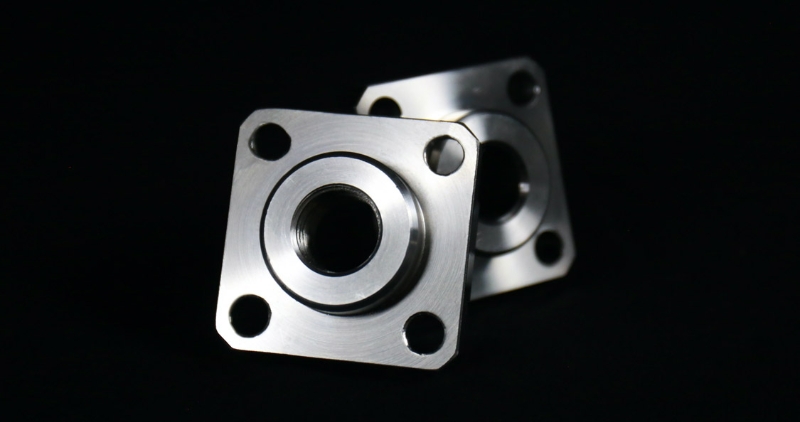

Advantages: high roundness accuracy (IT6-IT8), high efficiency in batch processing, lower cost, easy to operate.

Disadvantage: Only applicable to rotary body parts, can not process complex non-rotary structure.

Applications: shafts, discs, sleeve parts (e.g. motor shafts, gear blanks, bolts, nuts, flanges).

2.CNC milling

Advantages: Flexible machining, can handle flat surfaces, grooves, complex surfaces, high positioning accuracy (repeat positioning ±0.005mm), suitable for single piece/small batch production.

Disadvantages: batch processing efficiency is lower than turning, complex surface processing is more difficult to program.

Applications: Mechanical structures, mould cavities, aerospace parts (e.g. brackets, housings, impellers, cases).

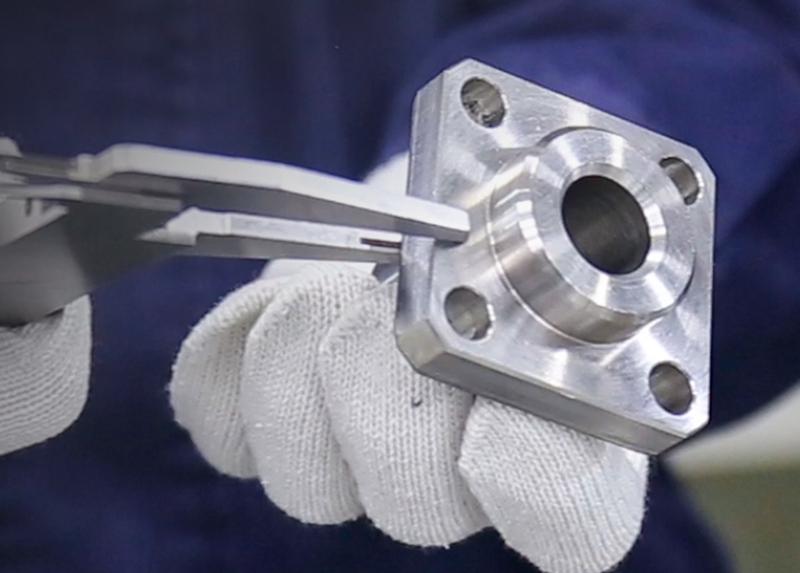

3. CNC Drilling / Boring Machining

Advantages: hole processing is targeted, high drilling efficiency, boring can correct the roundness error of the hole (accuracy of IT5-IT7).

Disadvantages: single function, need to be used in conjunction with turning / milling, deep hole processing is prone to skew.

Applications: assembly holes, positioning holes (such as flange holes, box through holes, bearing holes), often used as an auxiliary finishing process.

4. CNC wire-cut processing

Advantages: processing of high hardness materials (hardened steel, carbide), complex shapes (fine grooves, shaped parts), slow-wire precision is very high (± 0.002mm).

Disadvantages: low processing efficiency, high cost, only for thin-walled/small parts, materials need to be electrically conductive.

Application: Mould parts (convex mould, concave mould), high hardness precision parts (e.g. cutting tools, electronic component pins), fine structure parts.

5. CNC grinding

Advantages: very low surface roughness, top dimensional accuracy (IT3-IT5), can improve the wear resistance of parts.

Disadvantages: low processing efficiency, high cost, strict requirements for machine tools and cutting tools.

Applications: precision shafts, guide rails, mould cavities, high-precision gauges (e.g. gauges, screws).

6. CNC engraving

Advantages: can process fine patterns, text, good surface finish, suitable for small precision parts.

Disadvantages: limited processing depth, low efficiency, not suitable for large margin removal.

Applications: decorative parts, nameplates, precision mould textures, small electronic parts marking.

summaries

Each of the six CNC machining processes has its own focus: turning focuses on efficient mass production of rotating bodies, milling excels in flexible machining of complex structures, drilling/boring specialises in accuracy correction of holes, wire cutting breaks through the bottleneck of machining high-hardness shaped parts, grinding pursues the ultimate in precision and surface quality, and engraving focuses on the shaping of subtle decorative features. In actual production, according to the structural characteristics of the parts, precision requirements, production batch and cost budget comprehensive judgement, if necessary, through the combination of multiple processes, to achieve the optimal balance of processing efficiency and product quality.