When providing customers with exceptional sheet metal fabrication projects, SMILE must know exactly the properties of the metals used so that CHNSMIEL can determine which ones will achieve the desired results. These properties include considering metals that will rust so that we can avoid damaging the structures we fabricate.

What is rust?

——————————————————————

Rust is a compound made up of iron and oxygen. Rust occurs when specific types of metals are exposed to oxygen and moisture. The iron in the metal reacts with water and oxygen to form iron oxide, which is what we see as rust. Rust is a loose substance that flakes off easily, exposing more iron and leading to further corrosion.

Simply put, rust is a form of corrosion that can occur in any metal containing iron. Rust has a reddish-brown appearance and begins with a rough texture that eventually wears away and becomes flaky over time.

Why is rust a serious problem?

——————————————————————

Structural Damage

Rust causes wear and tear, which can damage any structure made from iron-containing metals. For example, over time, rust can replace certain parts of the metal with flaky powder, eventually making the metal weaker.

Rust is a loose substance that flakes off easily, exposing more of the metal's surface and accelerating the corrosion process. Over time, this cycle can lead to cracks or even complete fracture of the metal structure.

Functional failure

Rust is a poor conductor, so it affects the electrical and thermal conductivity of metals. For equipment that relies on metal to conduct electricity or heat (e.g., electrical wiring, radiators, etc.), rust can lead to degraded performance or even complete failure.

In environments where seals need to be maintained (e.g., pipelines, tanks, ships, etc.), rust can cause seals to fail, leading to leaks or moisture ingress, further exacerbating the corrosion problem.

Economic Losses

Once a metal structure begins to rust, the cost of repair or replacement can be prohibitive. Especially in large infrastructure projects, such as bridges, buildings or industrial facilities, maintenance and repair costs can run into millions or more.

Untreated rust can significantly shorten the useful life of metal products, forcing companies or governments to replace equipment or structures sooner, adding to the long-term economic burden.

What metals rust?

——————————————————————

Iron: The metal that rusts most easily, reacting with water and oxygen to form orange-red iron oxide (rust).

Steel: An alloy containing iron that rusts easily. The exception is stainless steel, which contains chromium, which forms a protective film against corrosion.

Cast iron: an iron alloy with a high carbon content that is more prone to rust and corrodes more quickly than ordinary steel.

Galvanised steel: coated with a layer of zinc, which corrodes preferentially and protects the underlying iron or steel. Once the zinc layer is depleted, the steel will begin to rust.

Ferrous alloys: such as certain tool steels and spring steels, contain iron components and will therefore also rust.

Which metals do not rust?

——————————————————————

Metals such as aluminium, copper, silver and gold do not rust, but other forms of corrosion can occur under certain conditions (e.g. aluminium oxidation, patina, etc.)

How to prevent metal from rusting?

——————————————————————

1. Coating protection

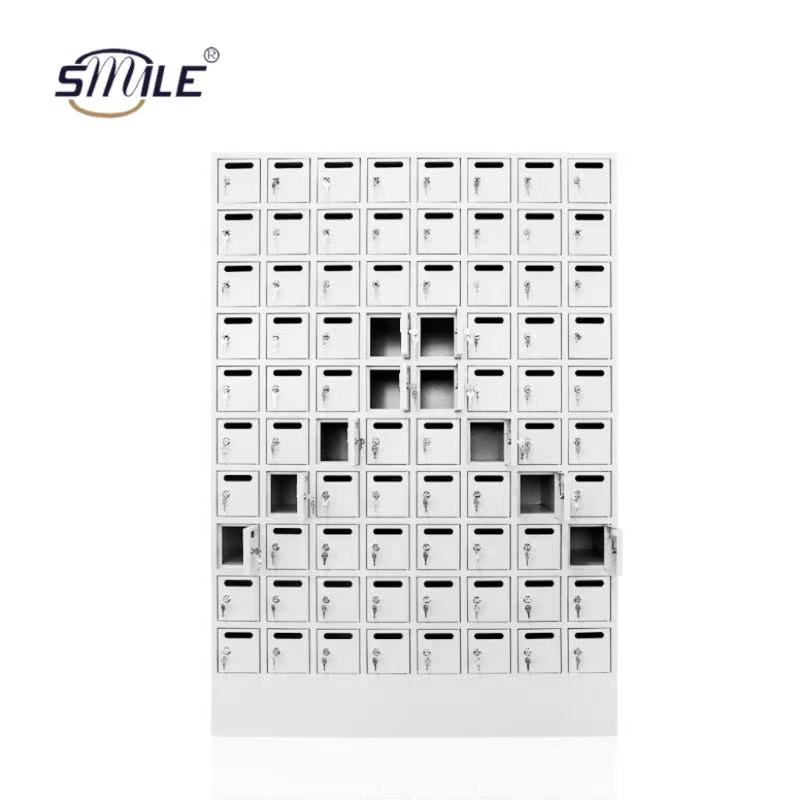

One way to prevent metal from rusting is to use powder coatings. Powder coating offers excellent corrosion resistance as it creates a barrier between the metal surface and oxygen/moisture, meaning it is less likely to rust.

2. Plating protection

Zinc plating: A layer of zinc is plated on the surface of iron and steel. Zinc reacts preferentially with oxygen and protects the underlying iron from corrosion. It is widely used in construction, automobile and other fields.

Chromium plating: Chromium plating is not only aesthetically pleasing, but also provides good corrosion resistance and is commonly used for decorative and functional parts.

Nickel Plating: Nickel plating provides excellent corrosion and wear resistance and is suitable for precision machinery and electronic equipment.

3. Keep dry

Try to keep metal products dry and avoid long-term exposure to humid environment. Dehumidifiers, desiccants or sealed packaging can be used to reduce humidity.